COST-EFFECTIVE PROTOTYPE DESIGN AND DEVELOPMENT

COST-EFFECTIVE PROTOTYPE DESIGN AND DEVELOPMENT

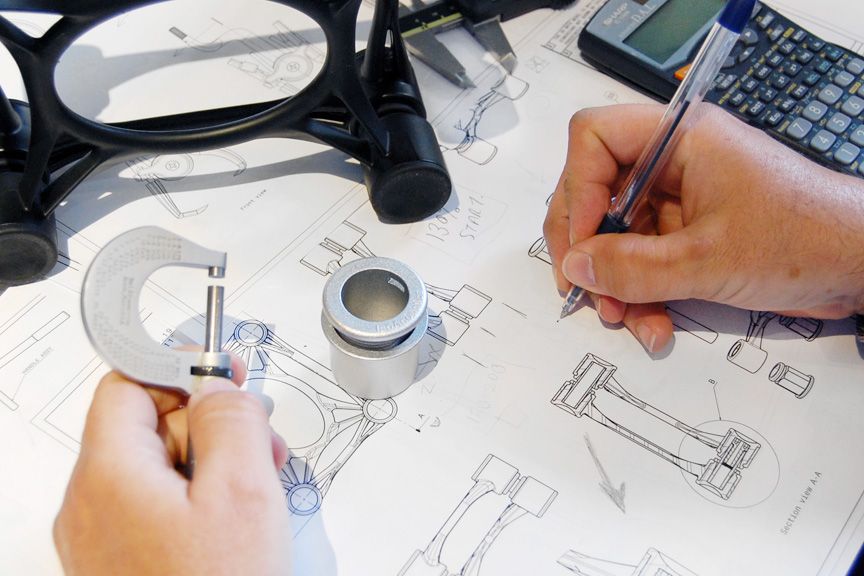

PROTOTYPE DESIGN AND DEVELOPMENT

PROTOTYPE DESIGN AND DEVELOPMENT

Sheet Metal Services can produce metal fabricated prototypes quickly and cost-effectively by our highly experienced team of engineers that utilise comprehensive 3D modelling and CNC manufacturing facilities.

We have a design team with skilled experienced engineers offering a dedicated service to our customers. We pride ourselves on providing a cost-effective solution to potential new products.

Production prototypes help to solve problems in a much more cost-effective way. We work with our customers to provide alternative manufacturing techniques to improve build quality and time savings to ultimately give a reduction in cost.

One of our biggest assets is our ability to solve problems and often our customers come to us because they have something they need to do but don’t know how. We use all of our experience to come up with valuable solutions. But not only that, we have a quick turnaround time too.

The Sheet Metal Services team helps streamline product design and testing while also ensuring that every sheet metal product is manufactured to the highest possible standards.

Our team’s main aim is to:

- • Produce detailed engineering drawings

- • Provide accurate bills of materials

- • Design and produce working prototypes

- • Liaise with customers to provide initial design to eliminate

delays or mistakes - • Material utilisation due to nesting of components

- • Reverse engineering to reduce costs

Software

- • Radan

- • Inventor 3D

- • Autocad

Our impressive client list is due to the level of trust we have built. We work with Project Managers as much as for them, sharing their goals and concerns, making their lives easier. It is all of these things that keep our customers coming back to us time and time again